For most young entrepreneurs, the manufacture of jockey silks—those brightly colored uniforms jockeys wear to indicate which owner they’re riding for in any given race—is probably not top of mind as a potential business opportunity. But when you own a clothing company and your family owns a Thoroughbred breeding farm, breaking into the obscure business is almost a natural step.

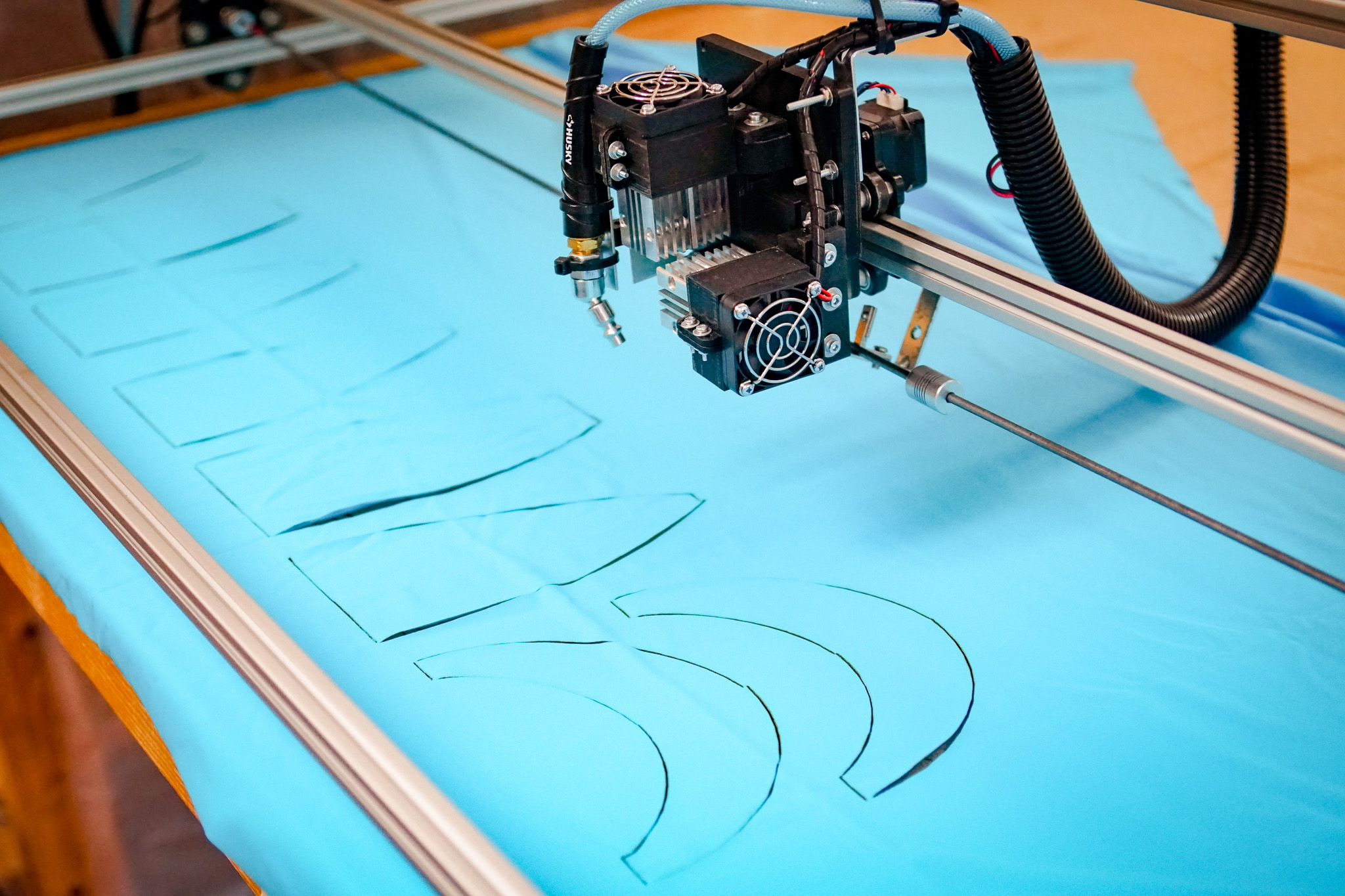

That’s exactly how Saratogian Michael Borisenok came to found Saratoga Silks Co, a company that makes custom silks right here in the Spa City. It all started in 2012, when Borisenok, whose family owns the idyllic Old Tavern Farm overlooking Saratoga Lake, launched GTS Clothing, an activewear brand that originally manufactured overseas. A few years in, he made the decision to bring his manufacturing operation (much) closer to home, and figured out how to do it all—design, cut, sew and ship—in house. He rebranded the company as Greatly & Co., and now sells his made-in-Saratoga athleisure online at greatlyandco.com.

From all that hands-on work with nylon and spandex, it was a short jump to the world of jockey silks, which—surprise—aren’t made of silk anymore. “With my family being involved with the racing industry and with my experience with small-batch manufacturing, I started to see that there might be an opportunity, or even a need, to better the process for jockey silks for owners,” Borisenok says. “And so I started to dip my toe in two summers ago.”

Jockey silks are regulated, at least in New York, by the Jockey Club, which has strict rules about what can and can’t go on a silk. (For example, the dots on polka-dotted sleeves should be two-and-a-half inches in diameter, and navy blue is not a permissible color, because it looks too much like black from a distance.) There are some 30,000 silks registered with the Jockey Club, and each new silk design must be different than the rest. First-time silk registration costs $125, and owners must renew their registration annually.

But most of that is out of Borisenok’s hands; the horse owner gets their design approved by the Jockey Club, and then comes to him to create it. What he can control is the speed with which he turns a silk around. “When owners or trainers get word of their horse being in a race at a certain track, it’s not a lot of time [before the actual race],” he says. “What I’m finding is the importance of a quick turnaround. They might have someone running in Saratoga, but then someone might be running in the Finger Lakes, and they need a silk out there within a matter of five days.” Saratoga Silks Co’s standard turnaround time is four to seven days, but Borisenok also offers 48-hour expedited turnaround for such cases.

While you haven’t seen Saratoga Silks Co silks on any Triple Crown winners yet, that doesn’t mean you won’t. (Any last-minute Travers entries out there? Borisenok’s got your jockey covered—literally.) “We’re not necessarily high volume at the moment,” the entrepreneur says. “But we’re at a place now where, whether it’s this summer or the summers that come, we can really create a better experience for everyone.”